Working method

Free quote plus working drawing

To quickly get an idea of the requirements, possibilities and costs, we are happy to prepare a no-obligation quote and accompanying working drawing. We do need a few things to do this properly:

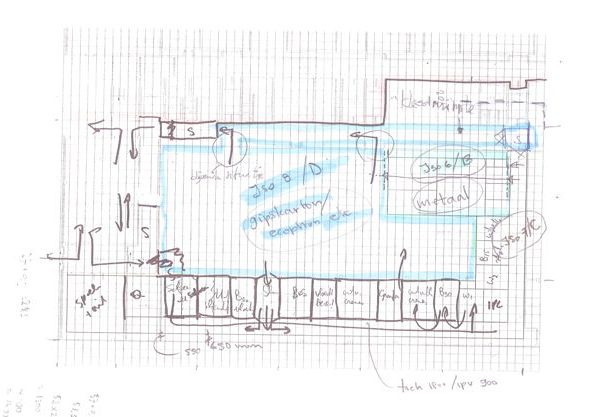

- A rough sketch of your plans, manual or digital, with a first impression of the cleanroom (inner box).

- An overview photo of the interior of the space in which the cleanroom will be placed, including the free height (outer box).

We will analyze your sketch and contact you with follow-up questions, for example about dimensions, circumstances and specific requests. Together we can determine a preliminary design, a schedule and a realistic price. And that is all without obligation.

Once the final design has been determined and the quote has been approved, we can get started.

Engineering and prefabrication

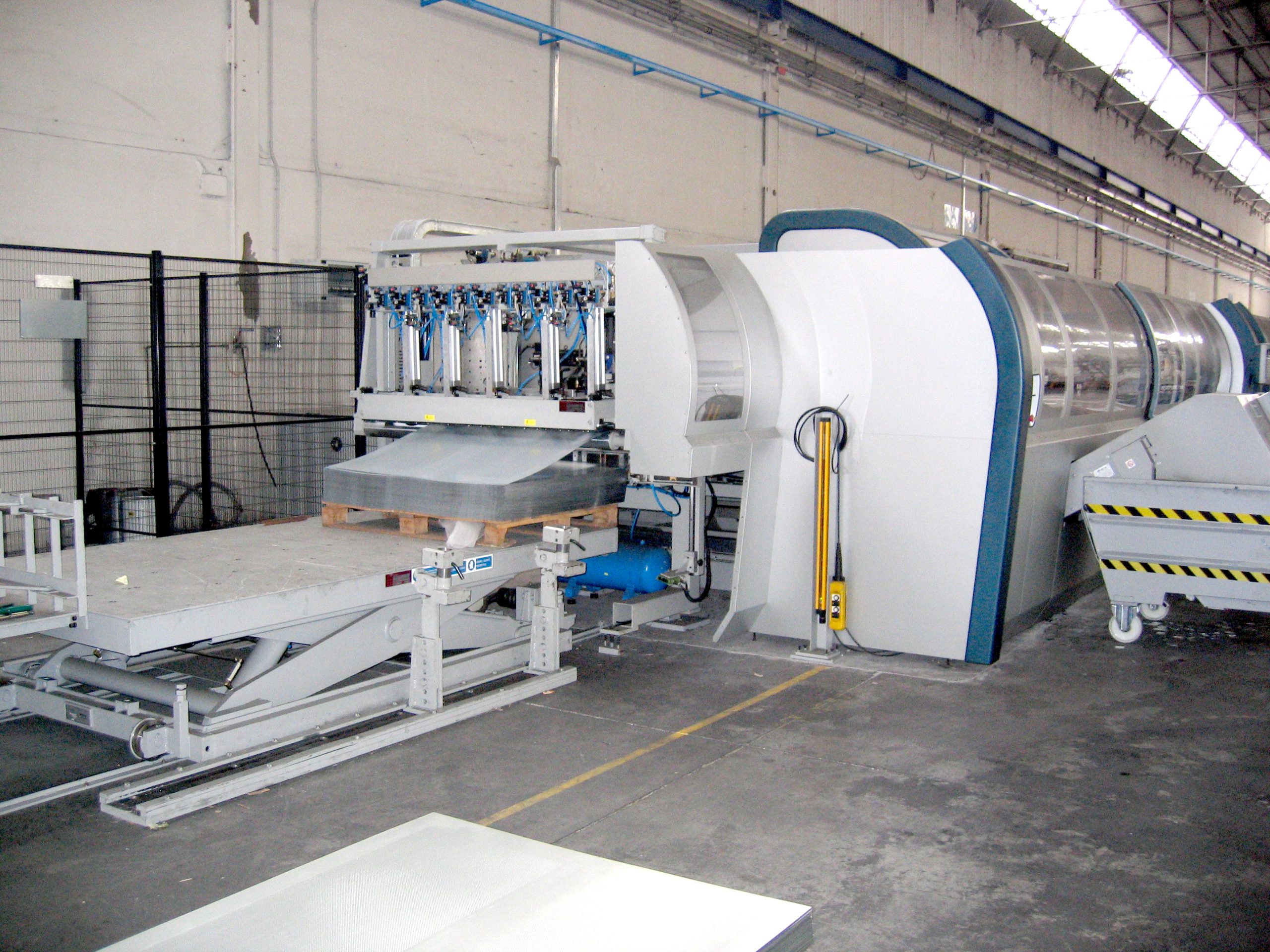

The working drawing has now been prepared digitally, and the final design has been agreed upon in consultation with you. Immediately after receiving the order confirmation, we start planning the work and industrial production. Since we assemble all cleanroom components industrially, we can optimize the process, deliver faster, keep costs low and minimize inconvenience at your location. Every component of the final product is stable, high-quality and in compliance with international certifications.

Getting started on site

Once the construction site is fully available, we will start the first on-site activities. We can now install the cleanroom:

- We map the location and start measuring and marking.

- The first prefabricated products are delivered.

- Once the flooring is ready, we will build the mezzanine.

- On this floor, the prefabricated air ducts will be assembled.

- Next, the air handling unit is installed.

- The structure is filled with modular walls, ceilings and windows.

- We install technical connections and the first light panels above the ceiling.

- The utilities are incorporated into the structure of the hollow wall.

The cleanroom is now ready for use. The complete installation of a cleanroom on site usually takes one and a half months.

An optimal process in 5 steps

How we create the perfect cleanroom

Delivering a cleanroom is a meticulous process. Over the past 30 years we have been able to optimize this perfectly. This means we can deliver quickly, while the process is smooth and the collaboration pleasant. And all this of course with a high-quality end result, internationally certified and incorporating the most modern, innovative technology.

We complete 5 steps, from design to realization. The first sketches and discussions lead to a technical spatial design. This means you can digitally ‘walk through’ the proposed structure and assess the design down to the smallest detail. The symbiosis between engineering and prefabrication ensures an optimal production process and perfectly predictable results. You can enjoy a Highcare cleanroom that we continue to monitor and keep up-to-date after delivery.

Branches

Precision industry

Our cleanrooms provide a certified and guaranteed clean environment, essential for the production of high-quality technologies.

Food industry

Mead Johnson sets the world standard with innovative baby and toddler food, produced and tested in a Highcare cleanroom in the Netherlands.

Space industry

Antwerp Space, a pioneer in the space industry, combines advanced technology with a custom-designed Highcare cleanroom for maximum flexibility and reliability.

Semiconductor industry

Highcare cleanrooms provide strictly controlled environments, which is essential for the production of high-quality, precision semiconductors in the semiconductor industry.

Optical industry

The optical industry, with major players like Zeiss and ASML, requires Highcare’s advanced cleanrooms for ultimate precision and clean production environments.

Medical industry

The production of medical devices and operating rooms requires Highcare’s extremely clean, controlled environments to prevent contamination and production errors.

Chemical industry

In the chemical industry, Highcare cleanrooms are crucial for ensuring a safe working environment, optimal product quality and efficiency.

What are the costs of a cleanroom?

Obviously a very relevant question, but one that is very difficult to answer directly. We will, however, do our best. What factors determine the price of a cleanroom? What are the periodic maintenance costs? What do we need in order to provide you with a realistic price estimate? Answering these questions will help us provide you with a good estimate of the costs of the cleanroom.

Everything in-house

a full-service solution

Top quality

always ISO certified

Fast delivery

no unnecessary delays

Modular construction

smooth implementation

1 First draft

The design process is fast and can be completed in a few days. You will receive a rough design and an initial price indication. During the follow-up process, we perfect the digital sketch plan and supplement it with your wishes and insights.

2 Digital tour

We create a highly detailed 3D design of your cleanroom. You can “walk” through this spatial digital drawing yourself and optimally assess the design before production starts.

3 Engineering & prefabrication

The system is pre-engineered, industrially prefabricated and delivered complete to the construction site. This makes on-site assembly fast and the overall lead time short.

4 Completion

You get a complete internationally certified cleanroom system. Due to our innovative Flex Grid system, all parts are easily dismountable and replaceable.

5 Service Track

We enter into an annual maintenance contract in which we agree on response time and MTTR. We monitor cleanroom conditions and keep filters, software and components in optimal condition. Statutory inspections are carried out on a regular basis.

An optimal process in 5 steps

How we achieve a perfect cleanroom

The delivery of a clean room is a meticulous process. Over the past 30 years, we have been able to optimize this perfectly. So we can deliver quickly, the process is smooth and the cooperation pleasant. And, of course, with a high-quality end result. Internationally certified and with the most modern innovative technology.

We go through 5 steps, from design to realization. The initial sketches and discussions lead to a technical spatial design. You can ‘walk through’ this digitally and thus assess the design down to the smallest detail. Thanks to the symbiosis between engineering and prefabrication, the production process is optimal and the result perfectly predictable. A Highcare cleanroom that we continue to monitor and keep up-to-date after delivery.

View roadmapBranches

Precision Industry

Our cleanrooms provide a certified and guaranteed clean environment, essential for the production of high-value technologies.

Optical industry

The optical industry, with big names like Zeiss and ASML, requires Highcare's advanced cleanrooms for ultimate precision and clean production environments.

Nutrition industry

Mead Johnson sets the world standard with innovative infant and toddler nutrition, produced and tested in Highcare's cleanroom in the Netherlands.

Medical industry

Medical device and operating room production requires Highcare's extremely clean, controlled environments to prevent contamination and production errors.

Space industry

Antwerp Space, a pioneer in the space industry, combines advanced technology with a custom-designed Highcare cleanroom for maximum flexibility and reliability.

Chemical industry

In the chemical industry, Highcare cleanrooms are crucial for ensuring a safe working environment, optimum product quality and efficiency.

SemiCon industry

Highcare cleanrooms provide strictly controlled environments, essential for the production of high-quality, precise semiconductors in the semiconductor industry.

Wat zijn de kosten van een cleanroom?

Obviously a very relevant question, which is very difficult to answer directly. But we are going to do our best. What factors determine the price of a cleanroom? What are the periodic costs? What do we need to give a realistic price estimate? This will still give you a good estimate of the cost the cleanroom.