Optimal results in 5 steps

1. Initial design

The design process is quick and can be ready within a few days. We analyze your requirements and a rough sketch provided by you, then we contact you for any follow-up questions regarding dimensions, circumstances and specific requirements. As the process moves forward, we refine the digital sketch plan and supplement it according to your needs and insights. This creates a detailed 3D working drawing, on the basis of which we can plan the process and determine a realistic price. All of this is entirely without obligation.

Once the final design has been approved and the quote has been accepted, we can get started.

2. Virtual tour

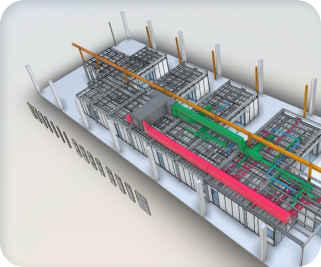

We create a highly detailed 3D design of your cleanroom. You can take a virtual ‘walk through’ of this digital space and carefully assess the design before production starts. This provides complete insight into the finished product as a whole and the details. Any changes can be easily implemented before production starts.

3. Engineering & prefabrication

A Highcare cleanroom is pre-engineered, industrially prefabricated and delivered complete to the construction site. This ensures quick installation and keeps the total lead time short.

Since we assemble all cleanroom components industrially, we can optimize the process, deliver faster, keep costs low and minimize inconvenience at your location.

4. Delivery

You will receive a complete and internationally certified cleanroom system. Thanks to our innovative Flex Grid system, all parts are easily removable and replaceable. This means that no demolition work is required and that we can deliver the cleanroom quickly and cleanly, minimizing any disruption on the job site.

5. Service programme

After delivery, we offer a maintenance contract in which we make agreements with you about response times and MTTR (Mean Time To Repair). We monitor the conditions in the cleanroom and ensure that filters, software and components remain in optimal condition. We also carry out regular statutory inspections, thus ensuring that your cleanroom always complies with the most rigorous standards.

In 5 steps to optimal results

The delivery of a Highcare cleanroom follows an optimized five-step process, from design to realization. It starts with a technical design that can be digitally reviewed. Thanks to the cooperation between engineering and prefabrication, the process is efficient and predictable, with an internationally certified and high-quality end result. After delivery, the cleanroom is continuously monitored and maintained.

The design process is fast and can be completed within a few days. We will analyze your requirements and rough sketch and contact you for any follow-up questions about such things as dimensions, conditions and specific requirements. During the further process, we perfect the digital sketch plan and supplement it with your requirements and insights. This creates a detailed 3D working drawing, on the basis of which we can plan the process and set a realistic price. All of this is completely non-binding.

Once the final design is approved and the quote is accepted, we can get to work.

1First draft

We create a highly detailed 3D design of your cleanroom. You can “walk” through this digital space yourself and optimally assess the design before production starts. This offers complete insight into both the whole and the details. Any changes can easily be made before production begins.

2Digital tour

A Highcare cleanroom is pre-engineered, industrially prefabricated and delivered complete to the construction site. This makes assembly fast and keeps the overall lead time short.

Because we industrially assemble all cleanroom components, we can optimize the process, deliver faster, keep costs down and minimize inconvenience at your site.

3Engineering & prefabrication

You will receive a complete internationally certified cleanroom system. Thanks to our innovative Flex Grid system, all components can be easily disassembled and replaced. This means no breaking work is required and we can deliver the cleanroom quickly and cleanly. As a result, on-site inconvenience remains minimal.

4Completion

After delivery, we offer a maintenance contract in which we agree on response time and MTTR (Mean Time To Repair). We monitor cleanroom conditions and ensure that filters, software and components remain in optimal condition. We also perform regular regulatory audits, ensuring that your cleanroom always meets the highest standards.

5Service Track

Schedule a no-obligation consultation

Contact us directly- Quick response

- Tailored to your situation

- A great deal of expertise

- Free quote possible