Step-by-step plan

A step-by-step plan for a three-dimensional tailored suit. A cleanroom is usually not standard but custom-made. The design is tailored to the specific requirements of the client.

Before we start the step-by-step plan, a HIGHCARE is modular, composed of replaceable components with its design specifically developed in accordance with the requirements for an international ISO certificate.

The system is movable which makes it also possible to lease this cleanroom.

In the past 25 years, the design has been further optimised and adapted to the latest technology as in units that can be remotely assessed and controlled, the flush airflow, the inert materials, the fire resistance (no PUR, PIR or PS), large glass facade elements for a clear and pleasant working environment, automatic sliding doors and “daylight” LED lighting. A step-by-step plan will guide you through the first phase, the design.

General

What makes a HIGHCARE cleanroom unique? The special air technology, a flat and smooth interior finishing and pipes that are located in the hollow walls or above the ceiling. A HIGHCARE is logically built on a fixed grid of 900 x 900 mm. Walls and ceilings are easy to keep clean and simple to open. This modular system consists of segments with an air technology that completely flushes the room with filtered air. A-state-of-the-art air conditioning system including a UVC unit against viruses such as Corona and other micro-organisms.

Competitively priced

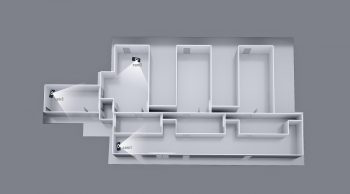

From sketch to 3D construction process. The first step in the step-by-step plan is to visualise your wishes by making a 3D design drawing. The purpose of this first concept is to stimulate the design process. You can watch the progress via a hyperlink. In consultation the sketch design will be further defined digitally. This process is quick and you will have a clear idea of the design within a few days by walking through the 3D rooms digitally, as it were. HIGHCARE chooses suitable materials and is competitively priced, but makes no concessions when it comes to; inertia, sanitary, flush and or/fire safety. The design takes shape through intensive interaction on further details. HIGHCARE likes to transfer knowledge and through a close collaboration this knowledge will grow on both sides and with that the quality of the design. Within a short period of time, this working method will result in a cleanroom.

Movable and easy to disassemble

This cleanroom system can be completely disassembled and relocated. There is a step-by-step plan for both assembly and disassembly; all rooms can be adapted, but also moved to a different location. A striking feature is the smooth finish of the interior with flat closed seams and tight transitions between windows, wall segments and ceilings. The ceilings and walls belong together and form a system.

Sale Leaseback, economic lifetime

HIGHCARE is suitable for a “sale and leaseback” construction because the system can be completely disassembled and reused. The only exception is the floor covering, which is considered part of the building.

Flexible

If a panel is damaged, it can easily be replaced or if you do not like the location of a sliding door, it can quickly be moved, even after three years, without drilling or sawing. Sliding doors, LED lighting, return grids, flush windows, air conditioning, ESD flooring; they all form one system, everything belongs together. A product that has proven itself in practice. A flat and smooth interior finish between ceilings, windows and wall panels. No concessions; a cleanroom.

Construction

During the construction phase, you will get to know the HIGHCARE installation team; specialist and enthusiastic employees who are used to working as a team. The short lines of communication and optimal information transfer through a single contact person – the Project Manager – will please you immensely. This is HIGHCARE’s approach. The cleanroom is industrially prepared and assembled on site. This makes for a fast construction process.

HIGHCARE hanteert het navolgende stappenplan:

-

1. The starting point; a simple manual rough draft

A sketch is a simple and practical element to start the design process; a conversation piece. It is either drawn by you or us, ad hoc, during the first meeting. During this meeting, aspects such as where the cleanroom will be located and the approximate size of the various cells, such as the production area and the various airlocks, will be discussed. In a cleanroom, the filtered air must be able to reach every point in the room without any problems. The materials are suitable for this type of environment. We may also discuss the target budget and the desired time of commissioning.

-

2. Establishing the cleanroom standard or classification

Establishing the cleanroom standard or classification and the sector are important for the number of supporting facilities such as airlocks and connections for air and electricity. Is it only dust (inorganic matter) that is important, or do micro-organisms (organic matter) also pose a risk? Each sector has its own specific requirements.

-

3. The first drawing of HIGHCARE

We will translate your sketch into a 3D drawing, the sketch design. HIGHCARE will send a hyperlink that allows you to view these digital drawings. This 3D programme will enable you to move around the cleanroom via your computer. In close consultation, we will optimise the cleanroom and thus create a final plan.

-

4. The basis for an indicative price

Cleanrooms are unique spaces and therefore price levels vary per square metre. Clients like to receive a cost indication at an early stage and do not want additional work. The 3D sketch plan is the basis for determining a practical budget price. This is followed by a concept offer for an independent standing system, a so-called box-in-box, including the cleanroom installation and excluding utilities and building-related costs, such as those for the utilities, location of the cooling machine and central heating boiler.

-

5. Engineering for a fixed percentage of the price; to be offset against the contract sum at a later date.

HIGHCARE will start the engineering of the cleanroom on a fixed fee basis. We call this the DQ phase, design qualification, according to an international working method. According to the design, the inside box is placed inside the building, the outside box. The price indication is based on a stand-alone cleanroom excluding connecting pipes and building-related costs.

-

6. Determining the facilities per room

For the DQ phase it is important to determine the desired connection possibilities (utilities). This concerns the consumption per output point, the simultaneity, the location on the walls and in the ceiling. We will calculate the light intensity at work surface level and the pressure cascade between the rooms. Also important is the circulation rate of the air.

-

7. Discussing and composing the final design, the contract sum and planning

At the end of the DQ phase, the cleanroom will be fully 3D dimensioned and all data known. In consultation with the client, the contract sum and the final design will be determined. The project will then be ready for implementation.